A Comprehensive Guide on How to Clean Aluminum Castings for Optimal Maintenance

Introduction: Aluminum castings are widely used in various industries due to their exceptional strength, durability, and lightweight properties. To ensure their longevity and performance, regular cleaning and maintenance are crucial. In this comprehensive guide, we will walk you through the process of cleaning aluminum castings effectively, using safe and efficient methods. Whether you’re dealing with stubborn stains, corrosion, or simply seeking routine maintenance tips, this article will provide you with the knowledge you need to keep your aluminum castings looking pristine.

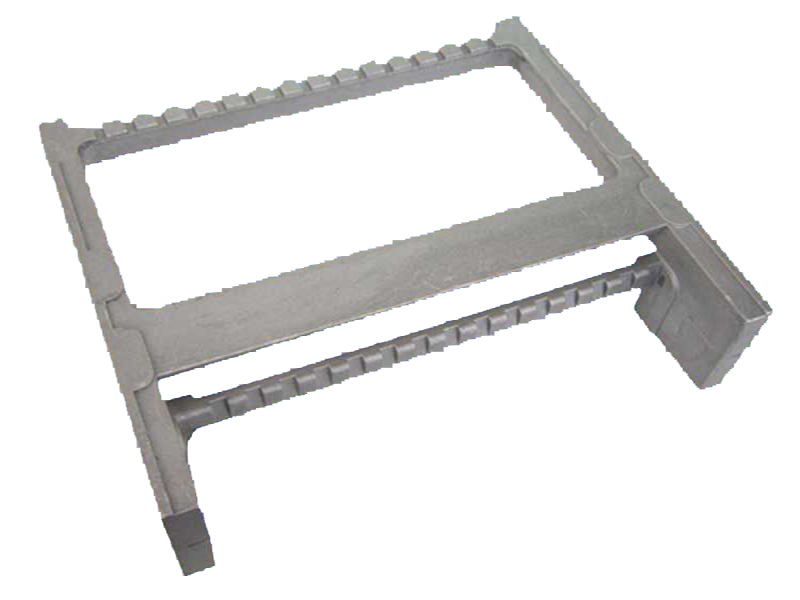

Understanding Aluminum Castings: Before diving into the cleaning process, let’s briefly explore the basics of aluminum castings. Aluminum castings are manufactured using a casting process that involves pouring molten aluminum into a mold to achieve the desired shape. Common types of aluminum castings include die-castings, sand castings, and permanent mold castings. These castings possess excellent corrosion resistance, heat conductivity, and mechanical properties, making them ideal for a wide range of applications.

Preparing for Cleaning: To begin the cleaning process, it’s essential to gather the necessary supplies and equipment. You’ll need a mild detergent, vinegar or lemon juice (natural acidic cleaners), non-abrasive materials such as soft brushes or cloths, and water for rinsing. Ensure you have a well-ventilated area and wear appropriate safety gear, including gloves and eye protection. Additionally, consider any specific precautions for the type of aluminum casting you are cleaning.

Cleaning Methods for Aluminum Castings: Method 1: Using a Mild Detergent Solution Start by creating a solution of mild detergent and warm water. Gently scrub the aluminum casting using a soft brush or cloth soaked in the solution, focusing on areas with dirt or grime. Avoid using abrasive materials that could scratch the surface. After cleaning, thoroughly rinse the casting with water and dry it using a clean cloth or air drying.

Method 2: Using Vinegar or Lemon Juice For a natural and effective cleaning alternative, you can utilize vinegar or lemon juice. Apply either of these substances to a soft cloth or sponge and gently scrub the aluminum casting. The natural acidity will help remove stains and restore shine. Remember to rinse the casting thoroughly and dry it properly to prevent any residue or water spots.

Method 3: Using Commercial Aluminum Cleaners There are various commercial aluminum cleaners available on the market. Follow the instructions provided by the manufacturer for proper application and safety precautions. These cleaners are specifically formulated to remove tough stains, oxidation, and corrosion. After cleaning, rinse the casting thoroughly and consider applying a protective coating or sealant for long-lasting results.

Method 4: Removing Stubborn Stains or Corrosion If you encounter stubborn stains or corrosion, specialized cleaners or rust removers can be effective solutions. Always follow the manufacturer’s instructions when using these products, as they may contain stronger chemicals. After removing the stains or corrosion, restore the appearance of the aluminum casting by buffing and polishing it with non-abrasive materials.

Maintaining and Protecting Aluminum Castings: Regular cleaning schedules are essential for maintaining the optimal condition of your aluminum castings. Develop a routine cleaning regimen based on the usage and environment of the castings. Additionally, consider applying protective coatings or sealants designed for aluminum to shield the surface from corrosion, oxidation, and environmental factors.

Tips and Best Practices:

- Prioritize safety by wearing appropriate protective gear and working in a well-ventilated area.

- Choose the cleaning method that is best suited for your specific type of aluminum casting.

- Store and handle the castings properly to minimize the risk of damage or contamination.

Conclusion: Properly cleaning and maintaining aluminum castings is vital for their longevity and aesthetic appeal. By following the techniques outlined in this comprehensive guide, you can effectively remove dirt, grime, stains, and corrosion from your aluminum castings while preserving their integrity. Remember to choose the appropriate cleaning method based on the type of casting and always prioritize safety by wearing protective gear.

Regular cleaning schedules, along with the application of protective coatings or sealants, will help protect your aluminum castings from corrosion, oxidation, and other environmental factors. By investing time and effort in their maintenance, you can ensure that your aluminum castings continue to perform optimally and maintain their visual appeal for years to come.

In conclusion, cleaning aluminum castings is a crucial aspect of their maintenance and longevity. By understanding the casting process, preparing the necessary supplies, and employing appropriate cleaning methods, you can keep your castings in pristine condition. Regular cleaning, coupled with protective measures, will preserve the strength, durability, and aesthetic appeal of your aluminum castings, ensuring their continued performance in various applications.

Remember to follow safety guidelines, choose the right cleaning method, and establish a routine maintenance schedule to maximize the lifespan of your aluminum castings. With proper care, your aluminum castings will maintain their functionality and visual appeal, serving you well for many years ahead.

Are you in need of high-quality aluminum die casting services? Look no further than CNM Tech China die casting manufacturer! Our team of experts specializes in aluminum, zinc, and magnesium die casting, as well as machining parts, metal stamping, and plastic molds making.

With over 18 years of experience, you can trust that our die casting products are exemplary and cost-effective. We employ advanced equipment and machinery to ensure the highest quality solutions.

We have been made many type of aluminum die casting, zinc die casting, magnesium die casting from flow meter housing and valves to lighting fixture parts, automobile parts, and decorative hardware, we manufacture a wide range of products to meet your needs. And, as an added bonus, we also export various aluminum casting, zinc die casting, and magnesium casting products, as well as machining parts and injection molded parts.

Don’t settle for subpar aluminum casting services. Choose CNM Tech die casting China manufacturer for exceptional quality and affordable prices. Contact us today to learn more about our services and how we can help meet your die casting needs!

Recent Comments